When a customer contracts us for robotic tank cleaning, the first step is often a detailed inspection of the space or tower itself. While this might seem like a simple preliminary measure, it can actually be a game-changer for facilities managers who aren’t use to having our technology at their disposal.

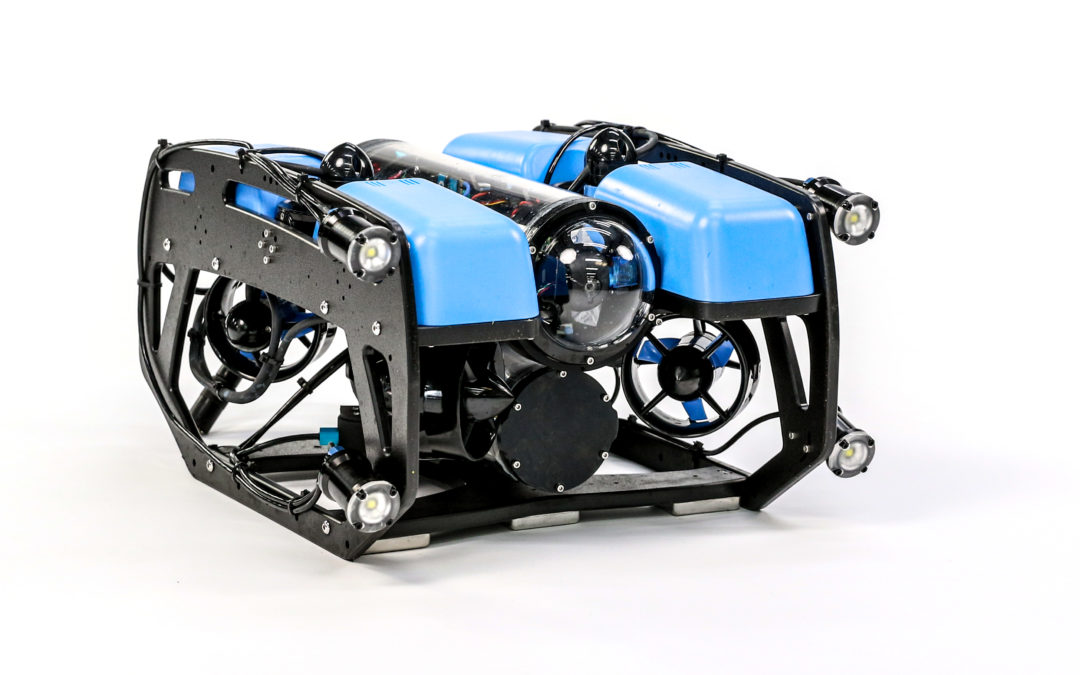

Before we explain why, we want you to understand the process. It involves taking a small robot (usually one that measures 1’ x 1’ x 18”), attaching high-definition cameras to it, and moving it through the submerged space. The resulting color-coded report will show sediment layers and types, along with existing debris and structural integrity.

With that short explanation out of the way, let’s look at what it is that makes robotic tank inspection such a big deal…

Small Robots Fit Into Tight Spaces

Many of the spaces we are contracted to clean have never been addressed because they are small, tight, or dangerous. Not only can our robots fit in places where humans can’t, but they can withstand heat, chemicals, and other environmental conditions that would be hazardous to a live diver. Using technology we can generate detailed inspections and assessments that would be otherwise impossible to obtain.

You Might Not Know What’s Inside Your Storage Tanks

Many of our customers have to rely on vague estimates are outdated analytics to determine sediment levels in their tanks. It’s not unusual, during an inspection, to find that there is more or less sediment than previously thought. Additionally, our robots might find debris, leftover construction materials, and other obstacles in the way. These could all pose significant logistical challenges if they remain hidden before cleaning begins.

Inspections Lead to Better Quotes and Maintenance

Since we do a better job of thoroughly evaluating what’s inside a tower or storage tank, it’s only natural that we can provide more accurate proposals and do a better job of actually cleaning the spaces. As with anything in life, it’s easier to complete a task thoroughly and professionally when you have the right information from the beginning. That makes things safer, faster, and (often) less expensive for the customers who hire us.

Thorough Inspections Can Improve Safety and Certifications

Having robots inspect and clean industrial tanks is certainly safer than using human divers. However, we can also help to reduce the risk of accident and injury by assessing the structural integrity of the unit itself. In some situations our reports can even be used for certifications as required by governmental or association parameters. The bottom line is that it’s always good to have accurate data about your equipment, and our robots can help supply the insights you need.

Want to Learn More About Robotic Tank Cleaning?

To learn more about robotic tank cleaning – a.k.a., robotic micro dredging – along with our equipment and processes, contact Sciphyn today. We’ll be happy to answer your questions, explain in greater detail, or provide you a quote for tank inspection and cleaning.