Adopting new technologies and processes can always be difficult. That’s especially true for plant managers and facilities supervisors, who work under tight budgets and production schedules. Making a mistake, choosing the wrong vendor, or being overly optimistic can cause big problems, so they have to get maintenance decisions right.

With that in mind, why would a person or organization decide to work with Sciphyn for robotic industrial tank cleaning rather than turning to existing, better-known alternatives?

We are glad you asked. Robotic micro dredging actually turns out being the clear choice when you consider the details. Here are a few we would ask you to consider…

Tank Cleaning is a Dangerous Job

Let’s start with the obvious: putting human divers into enclosed tanks and submerged spaces is an incredibly dangerous proposition. In fact, several people lose their lives every year while trying to clean industrial tanks, despite all the safety precautions that are put in place to protect them.

By using robots, we eliminate this risk altogether. Sciphyn has a 100% safety record because we don’t put humans in harm’s way. That’s important from an ethical perspective, of course, and also means lower insurance and liability payouts for our customers.

Robots Can Go Where Divers Shouldn’t

Not only are holding tanks and similar structures dangerous in and of themselves, but other hazards can exist for industrial tank cleaners. High heat, hidden debris, and corrosive chemicals are all prevalent in many industries.

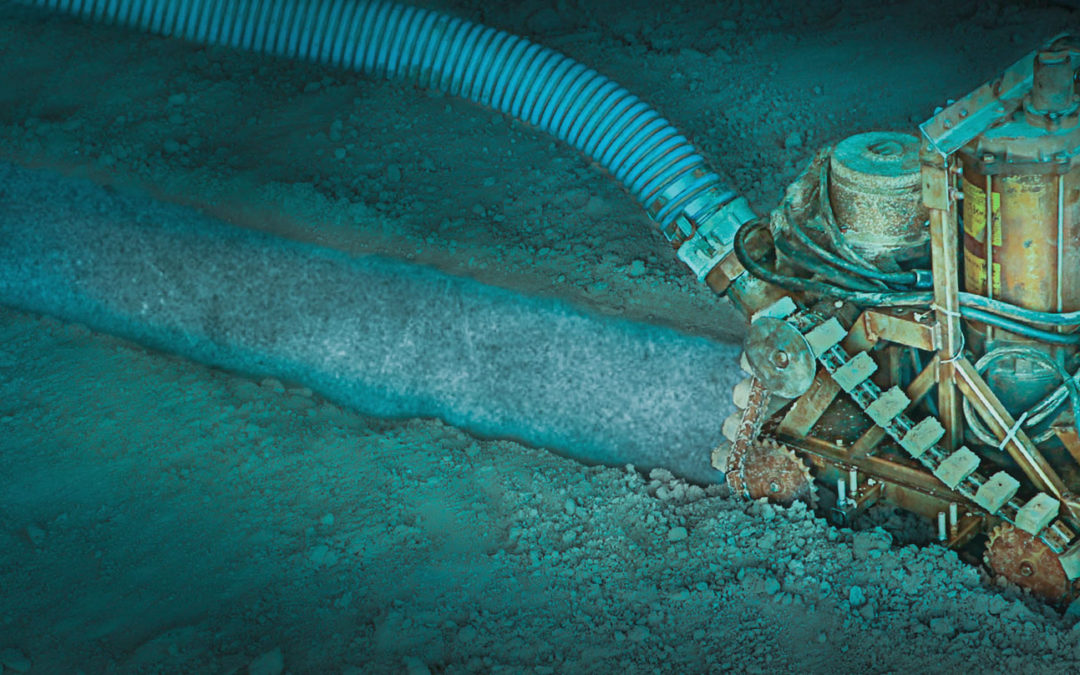

Each of these can be very problematic for a person trying to perform a difficult job under tight time constraints. For robots, though, they are simply obstacles that need to be navigated around. Tight spaces, toxic chemicals, and building material remnants are just part of the job. We can map them before work begins and then maneuver around them for a thorough cleaning with no risk.

Taking Equipment Offline is Expensive

Our machinery isn’t affected by most extreme conditions, and they don’t need to take breaks for meals and rest. You won’t have to run cleaning crews or safety personnel on overtime. Even better, our cleaning robots don’t generate any turbidity. So, existing water or other fluids won’t be disturbed.

Put all of these details together and you have a situation where your plant or facility can continue running as normal while our robots perform cleaning. You don’t have to go offline, alter your production schedule, or rush through the job and worry about the increased likelihood of injury or equipment damage. For many of our customers, those benefits amount to enormous cost savings.

The Bigger View on Robotic Tank Cleaning

When you consider what’s at stake, and the various tools and processes available, it’s easy to see that robotic tank cleaning is actually the safest choice – both for the people involved and your business as a whole.

To get a better sense of how our robots work, and the benefits we can bring to your plant or facility, contact Sciphyn today!